Branch

Select your branch

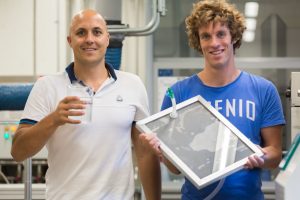

Innovator of the Month Interview with Swoxid

Swoxid is a Swiss pre-launch start-up led by Endre Horváth, developing filters to sterilize water. Their innovative material based on titanium oxide is activated using sunlight, and requires no electrical power. The filters can be used in remote places, and require little maintenance. The Ecole Polytechnique Fédérale de Lausanne (EPFL) spin-off is aiming to have a social impact on low income communities, where access to clean water is key to improve life quality and reduce child mortality.

Hello Endre and Claude, can you tell us more about your story. How was Swoxid born?

We met in 2009, at the swimming club here in Lausanne, and thanks to this hobby both of us have previously experienced the visual clarity and water odor in many swimming pools and natural rivers, lakes in multiple countries. I had recently started my PostDoc here at EPFL, and Claude was a PostDoc in Mathematics. But the roots of the project started earlier. I started working on the main material, titanium oxide (TiO2), during my Bachelor. The photocatalytic properties of TiO2 powder is well known since the 70s, with more than 40 000 scientific publications. This wonderful material is present in many everyday items such as plastics, paint and paper as a white pigment, it protects our skin in sunscreen, is present in emerging solar cells, such as dye sensitized and perovskite solar cells, and even in some edibles such as marshmallow or M&Ms as a colorant and anti-cake agent. The world production reaches 9 million tons per year. However, our innovation comes from the shape of our TiO2 particles. Unlike commonly used spherical particles, I have developed manufacturing methods to produce fibers of them, as well as upscaling the fiber’s production. Together with my colleagues and enthusiastic, talented students we have worked 10 years at EPFL on this process and during this time we envisioned the creation of Swoxid.

Can you tell us a bit more about the technology, and how the filtering panels work?

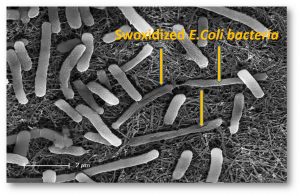

We first start by making a free-standing film out of the TiO2 fibers. Then we bake them together on a surface, to merge them into a mechanically robust mesh. This mesh has nanopores, small enough to avoid bacteria and other microorganisms to go through. Moreover, since TiO2 is a semiconductor with an optical bandgap in the solar spectrum, when illuminated with light, energy is released. The released energy splits water molecules into free radicals. They can decompose organic material during their very short lifetime. By this mean, any surrounding algae, fungi, bacteria or virus gets cut down into small pieces that can go through the filter. These leftovers are harmless to humans, making the initially contaminated water drinkable once it goes through the filter. After the filter is fabricated, we place it between two glass slides, and a panel to hold it all together. We then only insert an inlet on one side, and an outlet on the other side, place the panel in the sun, and let the water run through the filter using gravity!

Do these filters ever clog or need to be changed?

Here is their great advantage! First of all, they decompose any organic materials that might clog it. Furthermore, since the material is a ceramic, it is resistant to organic solvents, acids etc. You can easily backwash the filter with vinegar or any other acidic solution, and it will appear as new! However, since the water quality varies a lot from region to region, we are currently testing our prototypes with samples from different natural water sources in South Africa aiming the determination of the sterilization efficacy of the Swoxid panels. These tests are possible thanks to several foundations and the Swiss African Research Cooperation. We also have two motivated students here on campus conducting experiments with water samples from the local river in Lausanne.

Do you know if you have any competitors?

We have mainly seen similar technologies in air filtering, such as nonwoven nanofibrous TiO2 air-con filters prepared by electrospinning, but only few companies are tackling water filtering systems with this material. We are, of course, in direct competition with traditional water filtering methods. But we are aiming at a particular primary goal, which is social impact. According to the World Health Organization, worldwide, 780 million individuals lack access to improved drinking-water and each year diarrhoea kills around 525 000 children under five. A significant proportion of diarrhoeal disease can be prevented through safe drinking-water. We hope that this technology could help the poorest people living at remote places without safe and reliable water infrastructure. We can remove pathogens, like bacteria and viruses from their local water source, without the need of chemicals, electricity or boiling water.

A challenge in our project, is to define a new business model for such social applications in line with the targets of the United Nation Sustainable Development Goals. The people using the filters are our users, but can’t be our customers as they cannot afford such filters. Therefore, we are investigating less classical business models, as well as additional more lucrative ones, for example water filters for aquarium applications. Initial results show that we are able to filter out 40% more pathogens than the current state of the art commercial filters. This niche market enables us to demonstrate the viability of our technology, until we can apply it to other, bigger markets such as the food industry, air sterilization and wastewater treatment.

What did you learn in the process of creating a startup?

We are still in the process! Thanks to EPFL and the local ecosystem, we followed entrepreneurship trainings, and learned a lot on moving from our scientific engineering mindset, to a more entrepreneurial one. It is not just about the numbers, you also need to think about the product and how to present it in order to reach a broader audience. We enjoy the process of transforming basic research, into technologies that will actually help people. I see that as a dream of a scientist to work towards developing innovative products from promising results of basic science.

We recently participated in the ImagineIF competition at EPFL, which helped us evolve a lot. Beyond the coaching, we have also made many new contacts, that opened us doors to humanitarian organizations. It was a great leap forward for Swoxid!

What are your plans for the future?

We first need to establish a detailed validation of our prototype under different environments. This will enable to quantify how often the filters must be backwashed for example. We also want to hand-in the prototypes to more people that can test them, and make them as user-friendly as possible.

We hope, one day there will be statistics on the product, showing how many lives we can actually help. Even saving a single life would already be a great achievement for us!