Innovator of the Month Interview by Gianmarco Gatti and Alvaro Charlet.

CompPair is an up and coming Swiss startup led by Amaël Cohades, developing composite materials with healable and recyclable properties. The company was born as a spin-off of École Polytechnique Fédérale de Lausanne (EPFL) and its mission is to increase the lifetime of composite parts, reducing their costs and environmental footprint. The technology, developed at the Laboratory for Processing of Advanced Composites (LPAC) led by Véronique Michaud, can heal microcracks, which are at the root of fatal failures of composite materials, simply by heating them to moderate temperatures. CompPair products are textiles which have been pre-impregnated with this special technology, with the aim of producing full part applications. Scale up has already been demonstrated with various prototypes.

Can you tell us what composite materials are and how does your technology work?

Composite materials are for example glass, carbon or natural fiber textiles, where each layer is superimposed on top of the other. These layers are then consolidated by impregnating them with resin, so that the final output is a composite material made of fibers and resin. With this process, the materials can reach high structural mechanical properties while still remaining a lot more lightweight than metals. Therefore, applications are plenty: from sport and sailing, to transportation and windmills. However, there are some drawbacks: these materials are in fact really sensitive to damage and their restoration is complicated and costly. In addition, due to the complexity of the process and the high cost it requires, these materials are almost not recycled.

From the early 2000s, some people started to think about ways to make these materials healable. The main problem is that the superimposition of many layers prevents access to the damage. No efficient strategy was found to treat the damage without dramatically reducing the mechanical properties of the material and/or being competitive for a commercial application.

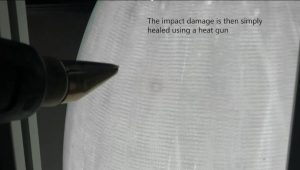

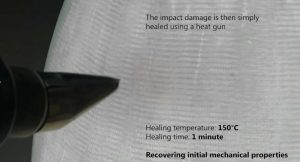

Five years ago, Professor Véronique Michaud decided to adopt another strategy for self-healing composites research in her laboratory. Heating moderately the composite up to 150°C should be enough to start the recovery reaction, without affecting the good mechanical properties at room temperature. I dedicated four years of my PhD research to this project and after many unsuccessful trials, we finally understood how to reach efficient healing of composites using heat together with mechanical properties similar to commercial systems. After additional research, our tests were working exactly as expected and we realized we had something very interesting: a composite with healable properties, competitive mechanical properties and with easy recyclability. Once the technology was patented, I decided to develop the project into a startup.

How do the diagnostics of composite materials work and how do you know if it requires healing?

Diagnostics, as well as healing, depend on the sector you are working in. In particular, there are three main cases: cyclic damage, preventive regeneration and safety in critical applications. In the first case, you have a part where you get cyclic damage, which means that you know how often you should heal your material. The prevention case is related to the use of your material instead. Let’s say you use your mountain bike for a day of downhill racing. You know there’s a high chance of having microcracks, since you could hit a rock for example; so you just preventively heal your material using a hair dryer in the evening in your garage for a couple of minutes. In the third case, which involves safety critical applications, like airplanes and windmills, there are established non-destructive techniques to scan the part for any cracks to see the damage directly. Now, once you find the damage, for instance in a windmill blade, you just need to locally heat the material to remove the cracks.

What market segments will you be addressing?

In principle, we could target any segment where composites are already being used. The beauty of our system is that we can implement it onto any fiber system, glass, carbon and natural fibers. We also have the capacity to slightly change the chemistry to adapt to all client needs. However, at the moment, we are focusing on marine and sports, but in the future we want to reach also the windmill, aerospace and automotive industries.

Do you have any competitors in this field?

There is rarely a new technology without competitors. But it is true, we are the first ones to have this additional feature on the market. However, we do have competitors, which are the big well-established semi product composite material producers. Nevertheless, we do have our technology as a key competitive advantage in our favor.

What kind of support did you receive from EPFL, or other mentorship programs here on campus?

We quickly realized we needed a prototype to show the working principles of our healable composites. Thanks to the support of the ENABLE program of EPFL in summer 2018 we managed to develop our model [the dome-shaped part in the figure, which is typically used in the aerospace industry]. Later on, I applied for coaching at EPFL Innovation Park, and then continued to get great support from the LPAC laboratory. After that, we won the first stage of Venturekick in February 2019. In June 2019, we then received an Innogrant from the EPFL Vice Presidency for Innovation and an InnoBooster, from the Gebert Rüf Foundation. Therefore, we secured enough funding for an additional year, but if we want to scale-up the production we will certainly need additional resources.

You are speaking at the Innovation Forum Lausanne Annual Conference, can you give us a sneak-peak and tell us how your application is more sustainable than traditional composite materials?

There are two key aspects: firstly, we can increase the lifetime of our parts, which dramatically reduces CO2emissions and the environmental footprint of the application. Secondly, CompPair’s mission is to provide long-term, full circularity, of the material: unlike most traditional composite materials, we can easily separate the resin from the fibers, thus greatly increasing the recyclability of the composite part.

Can you tell us more about your team?

We are expanding quite quickly! On the technical side, Robin Trigueira, Co-founder, takes care of product development, proof of concept, demonstrations and pilot testing. Cecilia Scazzoli, is finishing her Masters, and writing her thesis related to the product we will be launching. She will continue with us early next year. On the business development side, there is Bertille D’Agay and Nicolas Gandar, who I met at the InnoSuisseBusiness Concept course. They take care of finance, sales, marketing and management. I am supervising the whole project. Prof. Véronique Michaud continues to support us with many different aspects, from science, to product, and industry. In addition, we are being well advised by experts! Also, many students are linked to the projects, which helps to boost our venture! We are quite a big team already, but complement each other well and get along well together.

Right now I’m working on obtaining a seed round from March up to Summer 2020, to be ready for when we will have the beta version of our product by the end of 2019 and to welcome our first customers in early 2020.

How has your personal experience been so far leading CompPair over the past year?

It is really demanding, but I love it. When you do 4 years of research and you suddenly see a spot for integrating it into a real commercial application, well, that’s the dream. Even if I had other great things that awaited me after the PhD, I knew that if I had left such a great opportunity, I would have always regretted it.

Do you have any suggestions for the next entrepreneur in Material Science?

At this point, I need to thank my research advisor, Véronique Michaud. She is an incredible scientist. She always told us that in addition to doing deep science, we should be able to upscale our system to meet industry requirements. We can process samples at a research level but with industrial relevant processes. My suggestion is: always think in terms of applications, even if you don’t immediately see it in your research, because you never know what you might reach in the future.